In the race to repair our failing infrastructure, BIM and computational design can help us build faster, better, and cheaper

– Mac Little, Computational BIM Lead and Anton Dy Buncio, COO, VIATechnik

The transportation infrastructure of the U.S. is approaching failure at an alarming rate – the 2017 Infrastructure Report Card issued by the American Society of Civil Engineers (ASCE) graded the various forms of transportation infrastructure a D+. Even if we narrow the scope to bridges only, the American Road and Transportation Builders Association estimates that 7.6% of bridges – some 47,000 bridges throughout the US handling around 178 million daily crossings – are structurally deficient and in need of major repairs. At our currently decreasing rate of repair, it would take 80 years to fix these problems, to say nothing of the additional 188,000 bridges in need of smaller repairs. This is an unacceptable timeline. At VIATechnik, we have been focused on utilizing computational BIM workflows to tackle this problem. Using Grasshopper, Rhino 3D, and Tekla Structures, we are merging structural engineering and computational design to disrupt the way we design and build bridges. We believe this workflow can significantly reduce the resources and cost required to replace our failing infrastructure.

Typical Bridge Design and Detailing Workflow

With some exceptions, a standard highway

bridge is built in precast concrete sections lifted into place by crane. This

includes the superstructure of piers and girders that support the road surface.

Each of these pieces must be carefully designed to certain structural and

environmental requirements, creating complex rebar designs that must be

reviewed and tested during the design and shop drawing phase. Today this is

typically performed with 2D software such as AutoCAD or Microstation. A bridge

design is broken into precast sections, then into typical and atypical details

that are individually drafted and placed into a digital sheet set. A model

based on these drawings can be created and analyzed for capacity in a 3D

modeling platform, but all changes or findings must be recorded and tracked

back to the separate drawing creation platform. Introduce any amount of

complexity in the bridge geometry and the atypical details quickly outnumber

the typical ones and the workload increases exponentially. Neither of these

programs considers constructability or rebar clashing; they are typically

purely documentation tools or rote structural analysis. And they are being used

on significant projects. We routinely see $50 million bridges with complex

geometry approached with little more technological innovation than a

hand-drafted set of blueprints.

This

workflow is almost entirely manual, and even if we suppose portions might be

attempted in a 3D software such as Civil 3D, adapting to changes can be a

weeks-long process. After all, a change in overall bridge geometry means every

section needs to be modified accordingly. This involves coordination across

multiple digital files and data within those files. Even if you know exactly

what to do and make no mistakes, the sheer amount of time this takes is

astonishing. Moreover, exceptionally complex bridge designs can present

problems from a purely geometric point of view – multiple layers of curved

geometry are harder to initially analyze and draft in 2D and therefore more difficult

to modify. This can lead to compromised designs from the outset, as more

complex – but more efficient – designs are eschewed in favor of options more

easily fit into 2D confines.

BIM and Computational Design Workflow

But what if there were a way to automate the entire process of modeling and shop drawing production, irrespective of bridge geometry? Our client, approached us with a bridge design that was proving difficult to model accurately in our 3D software due to the complex curvature of its intermediate diaphragms. Using a combination of Excel, Grasshopper Parametrics, Rhino 3D, and Tekla Structures, our team created a live-linked model that uses only the real-world elevation points of the road surface to generate a complete bridge geometry.

These elevation points are entered into Excel, which feeds into a customized Grasshopper algorithm that generates a conceptual massing model complete with structural girders and piers. The Grasshopper-Tekla Structures live-link plugin allows Grasshopper to drive geometry natively in Tekla, eliminating the need to re-model from scratch. The model can then be populated with rebar to an extremely high level of detail, all of which is automatically numbered and output into drawings for fabrication.

With

this workflow, changes were incorporated in drastically shorter timeframes over

traditional means. The entire process, from elevation adjustments to updated

shop drawings, is a matter of days. It requires less dedicated modeling staff,

freeing resources for other projects. This greatly reduces the opportunity for

human error which reduces time spent correcting mistakes in drawings sets and

in the field. Further, this raises the possibility of tighter and more accurate

construction schedules, saving time, capital, and labor while increasing the

rate at which projects can be completed.

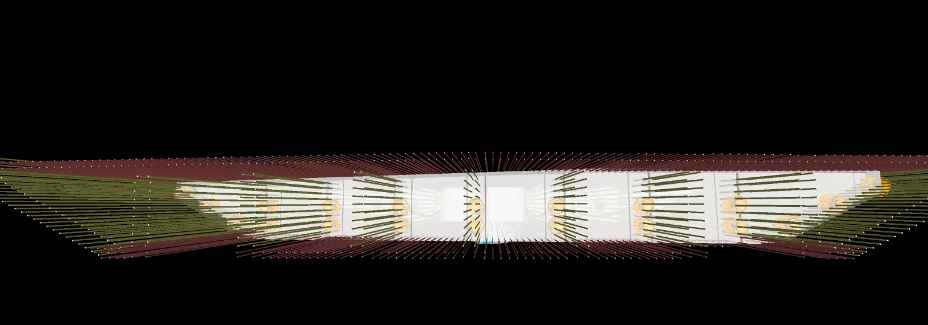

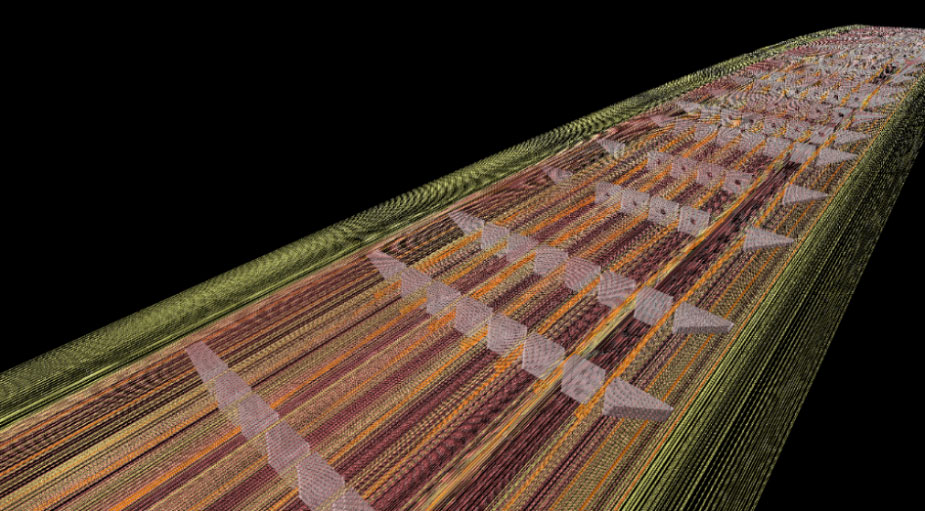

3D views of bridge rebar, diaphragms and various sections created in Tekla, bridge tendons modeled in Revit Photo: VIATechnik

The Future of Infrastructure

Since the inception of the ASCE Infrastructure Report Card, a passing grade has been issued only once – a C in 1988, the first year of the report. Our present way of working is not working at all. At stake is some $4 trillion in GDP and 2 million jobs estimated to be lost by 2025 if the infrastructure investment gap is not closed. But it is not simply a question of resources – it is a question of strategy. New workflows like those we are pushing with our clients can increase our rate of infrastructure repair exponentially. It is time for us to educate governments on the possibilities of BIM, computation design, and automation so they can craft policy demanding the disruption of traditional means and methods. VIATechnik is already beginning to see this in places like New York and Arizona – teams are now required to deliver projects through VDC methods. The future of our infrastructure relies on the proper implementation of a new way of thinking, and with this combination of industry innovation and education we can get our nation’s infrastructure from a D+ to at least a B+.

Responses